My cousin invited us over during the weekend to her kid's project day at his school. The theme was "Community helpers". 5-6 kids took up one community activity and had to explain the role of the respective helper in the society. Postal service, Police station, Fire Station, Hospital, School, Agriculture were some of the stalls on display. It was a pleasant surprise to see my nephew take up the role of a carpenter :)

|

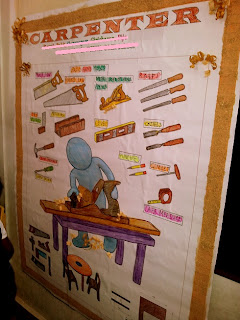

| Carpenter - A Community Helper |

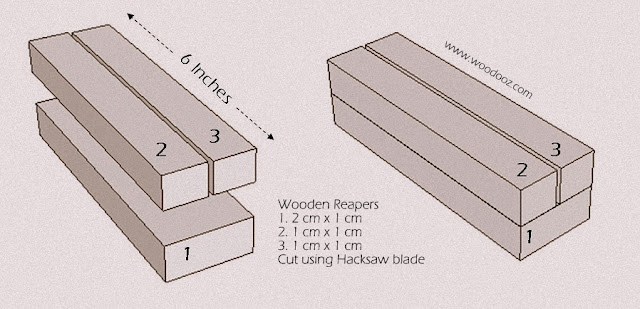

"I am a carpenter and I do various kinds of wood work. I use these tools to build houses, cots, shelves, chairs", is what the kids were explaining to the onlookers. They had all kinds of woodworking tools on display including a drill, hammer, planer, clamp, chisels, screw drivers, hand saw and more. They also had miniature models of a shelf, couple of chairs and a table. And they were well prepared to take up any question related to what was on display in their stall.

|

|

We went there to cheer for and encourage my nephew and were pleasantly caught unawares to see him explain an activity that I have, in recent times, been so passionately taking up. I liked it that the parents chose a respectable uniform for the mini carpenters despite many insisting on going with the cliched "Lungi". Carpenters, much like many others, work towards making our lives much easier and it is a positive sign to see this thought being instilled in the kids.

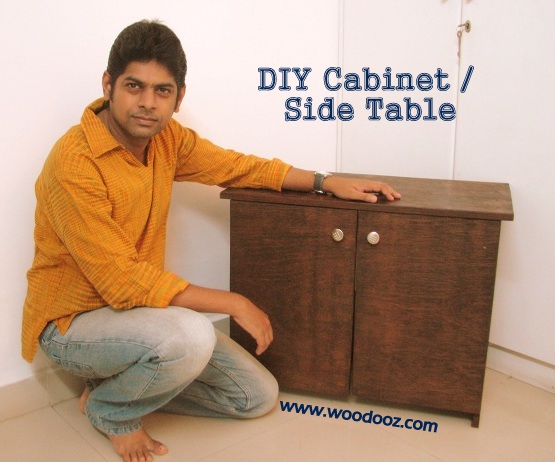

Do you agree that carpentry in India can be beyond just a profession and can be a leisure activity that anyone can indulge in ? Or think it is just another myth ? Leave me your comments.

Do you agree that carpentry in India can be beyond just a profession and can be a leisure activity that anyone can indulge in ? Or think it is just another myth ? Leave me your comments.

Due credits : While I did take the pictures, the credit for the charts and the entire set up goes to the parents of the kids and the school faculty.

Linking in : Colours Dekor