Hobby woodworking is not so much of a well-known domain in India. Easy access to labor, lack of readily available DIY kits, lack of awareness, absence of an active hobby community, lack of time are some of the reasons why this terrain is largely unexplored. Or so I thought. When I started my first project, I was skeptical because of these same reasons. However, it was a revelation as I moved on and have now come to enjoy it with fervor. Here is the list of four things that created a block in my mind that I strongly believe are merely myths.

Myth 1: Tools are not available

Tools required depend on the project that one is undertaking.

Hobby woodworking can also relate to smaller projects which eliminates the need for high end tools or machinery. However, knowing what tool one needs for a certain activity is essential. Unlike the western countries where you can walk through aisles in retail outlets to pick and choose your tool of choice,

in India, the challenge is to specifically ask the hardware vendor what you need. From what I have seen, there is absolutely no dearth to the kind of tools that get sold in Indian hardware stores.

Myth 2: Information is not available

In this world of Internet era, no amount of information is beyond the reach of an individual. Youtube and Google can throw millions and millions of tutorials for you to choose from. Right from

how to buy a tool to how to use it to how to build a certain piece of furniture, everything you can imagine is available at a detailed level. Woodworking DIY is an established concept elsewhere and you would find what you need in every corner of the WWW.

Besides that,

local carpenters carry a wealth of information with them. Though they are hesitant to share their trade secrets with hobbyists, there is so much that you can learn through observation. Also, of late,

woodworking workshops for enthusiasts (will save the details for another day) have also sprung up in some cities.

Myth 3: Labor is inexpensive, so why sweat?

Hobby woodworking is most certainly not an alternative to cheap labour. It is like any other hobby.

You don’t paint a canvas because buying an original Picasso is expensive. It is about being passionate and taking pleasure in your indulgences that enable you to explore your creative potential. On a different note, labour is indeed not cheap. Some of the quotes that I have received :

Rs 500 for painting a 2 ft x 2ft low table, Rs 800 for installing glass doors for my TV unit, Rs. 1500 for erecting a frame around the cot (for mosquito netting).

Myth 4: There is no active community

I realized over a period of time that the number of Indian blogs in this niche is limited. However, that was no indication to the number of folks indulging in Woodworking. I found out that there are indeed people to whom I can reach out.

- The DIY Woodworking India group is now becoming a very active Facebook group with hobbyists, enthusiasts and experts exchanging their WIP projects and expert tips. If you are looking to join an online community, THIS IS IT.

- Indranil Banerjie is from Noida and manages a hardcore woodworking blog. Some of his projects are big and very very functional.

- Vinay is another blogger from Vellore and makes some really fun projects like wooden toys and Wooden Wagons for kids.

- Am sure at least one or two of you would now say,"Hey ! my father was never a blogger. But he was way into carpentry and did everything that he could inside our home."

- And that is the point. There are more and more individuals who have always been into carpentry and there are many who show keen interest towards it. Just that they never had / have a blog.

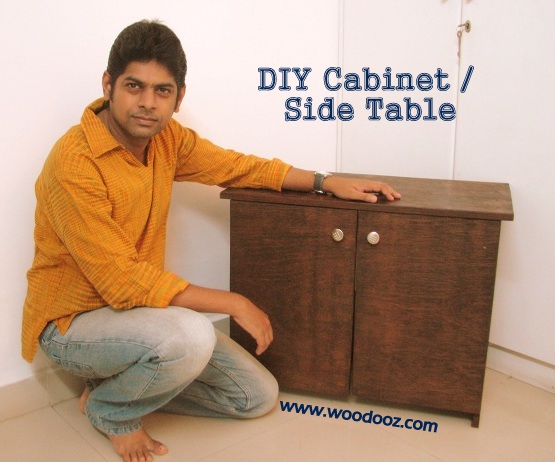

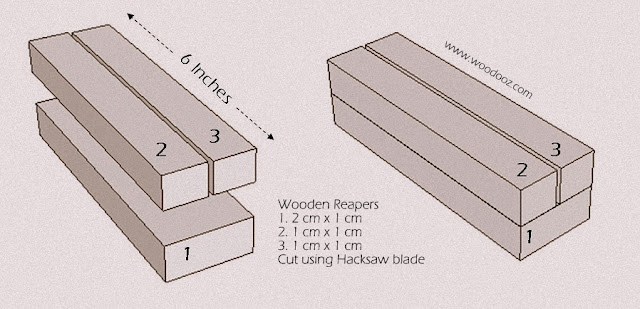

Woodworking is fulfilling and functional at the same time. If you are indeed thinking about hobby woodworking, Good luck. Start with smaller projects before you can venture into the bigger ones. Do not let these myths hold you back. Explore and experiment. India has all things in place for you to quench your thirst for DIY woodworking.

Do you agree with my views ? Do share your thoughts. I am game for a healthy debate on this topic. And think there are other myths too ? Leave a comment.

+DIY.jpg)

.jpg)