(Note : I have started a new series on how to make a Golu Padi. I explain the process in three steps. Do check out the 1st post in the series for a better understanding)

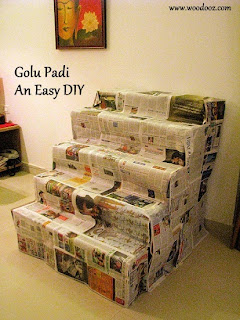

This time of the year, with everyone being busy with arrangements for Navarathri, one of the major task at almost every household is setting up the steps for arranging the dolls. If you have been setting up Golu for years together, am sure you would not have much of an issue with the steps. However, if you are doing it anew (like us) and have no major time at your disposal, here is a 5 step padi that you can build with planks, cardboards and everyday furniture around the house.

This time of the year, with everyone being busy with arrangements for Navarathri, one of the major task at almost every household is setting up the steps for arranging the dolls. If you have been setting up Golu for years together, am sure you would not have much of an issue with the steps. However, if you are doing it anew (like us) and have no major time at your disposal, here is a 5 step padi that you can build with planks, cardboards and everyday furniture around the house.

We had leftover planks and card boards and the idea was to not spend time and money on Padi. Last year was the first time we kept Golu in our new home and maybe as we collect more dolls, we will look at a more permanent step arrangement. For now, the make shift one works good for us. Do share your thoughts in the comments section.

+DIY.jpg) |

| Make your own Golu Steps |

1. Materials used for the steps

- Bottom step - Center table

- Step number 1 - Card board sheets (The ones I used for demo for my Clock DIY video)

- Step number 2 - 6mm Plywood planks

- Step number 3 - 19 mm Plywood planks

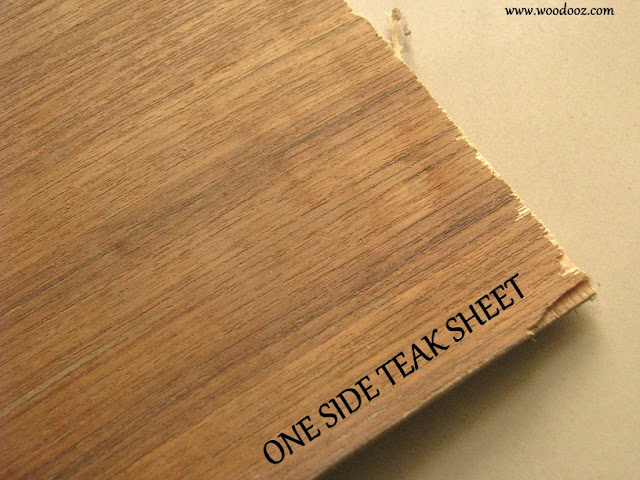

- Top most step - OST sheets

2. Mounting the planks

- Bottom step - The center table itself formed the bottom most step

- Step number 1 - Used two cardboard boxes (placed on the center table) on the corners and piles of papers to support the Carb board sheets

- Step number 2 - Stacked up bricks (on the center table) on which the 6mm plywood planks were placed

- Step number 3 - Placed dining chairs on opposite ends and supported the 19mm plank on the back rest

- Top most step - Placed two modas on the dining chairs, added shoe boxes and books for height and for holding the OST sheets

.jpg) |

| Make your own Golu steps using planks and everyday furniture |

The idea here was not to showcase any carpentry skills. The purpose was to build the steps with whatever we already had in ways that anyone can do. I know it doesn't look great on the inside. But it certainly serves the purpose after appropriately covering it up. We have for now covered the setup with news papers and we will soon use the traditional white dhoti on top. Work is still in progress and thought there is no better time than now to post this.

How do you do your Golu steps ? Already have a knockdown setup ? Plan to get it done for the first time ? Leave us a comment.

How do you do your Golu steps ? Already have a knockdown setup ? Plan to get it done for the first time ? Leave us a comment.

Here is two DIY projects on Golu steps that we loved while browsing the net for ideas :

How to build Navarathri Golu steps by Love and Lentils

Linking in : Colours Dekor

- A recycled kurta lampshade you can use to light up your golu

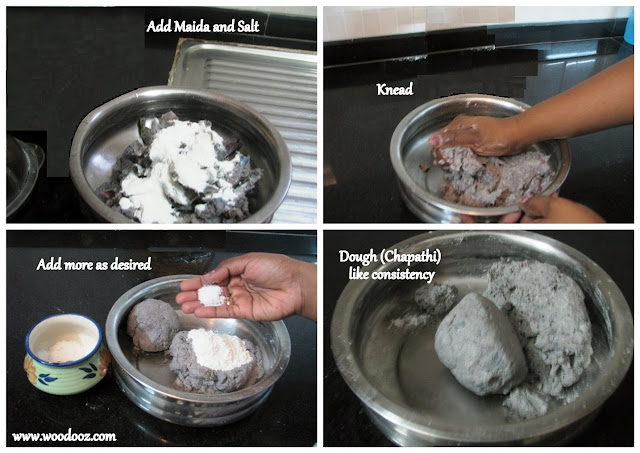

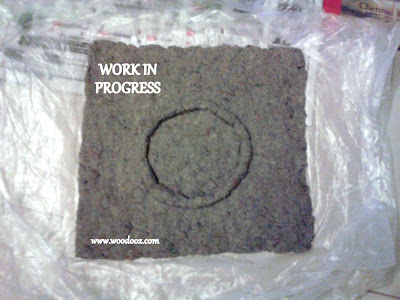

- Make Paper Mache dolls to display during Navarathri

- As inappropriate as it may sound, wine bottles can make up for good golu items

- Display your Warli Por Painting skills this Navarathri

Linking in : Colours Dekor