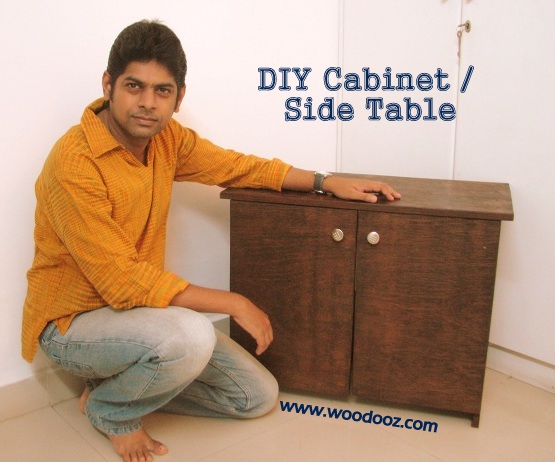

As we step into the fourth year of Woodooz tomorrow, we wanted to look back at our most favorite project ever. This center table - The first thing we ever made. Still remember how when we started, we had absolutely no clue how to go about it. The internet had loads of information, the plywood store guys were not so helpful and we had no expertise whatsoever to even think that we could pull it off.

It has been an enriching ride here in Woodooz with learning opportunities coming our way every other day. It is this table that made us ask the question, "Can we make it ourselves?" every time we wanted something for the home. Three years on, and we still proudly use this table in our living room.. It may have its minor defections, but to know that we built it from scratch has always given us immense pleasure.

The table has seen many a steaming coffee spills and yet has stood the test of time. Many a dinners have happened around it. We have used it for all our Scrabble and Rummy sessions. And to think how many conversations it has started only makes this table a personal favorite of ours.

The table has seen many a steaming coffee spills and yet has stood the test of time. Many a dinners have happened around it. We have used it for all our Scrabble and Rummy sessions. And to think how many conversations it has started only makes this table a personal favorite of ours.

|

| Center Table / Coffee Table |

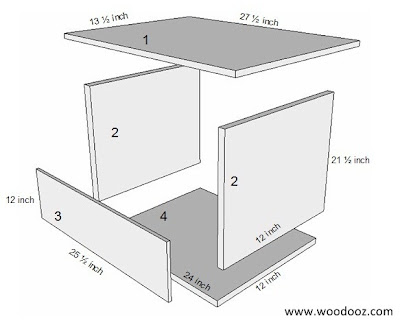

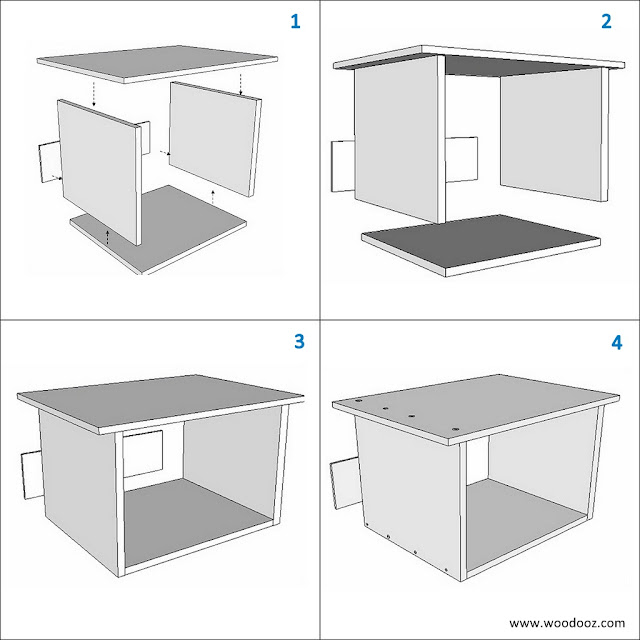

While I intend to do a "How to build your coffee table" using Sketchup illustrations (unfortunately, we never thought we would have a need to put up a DIY post ever and so we never took pictures at every step), I will leave you with the details on the materials, tools that I used to get this done. Do remember to leave us a, "Happy Blog Birthday" message and make our day :)

| Materials used | Tools used | For the finish | Miscellaneous |

|---|---|---|---|

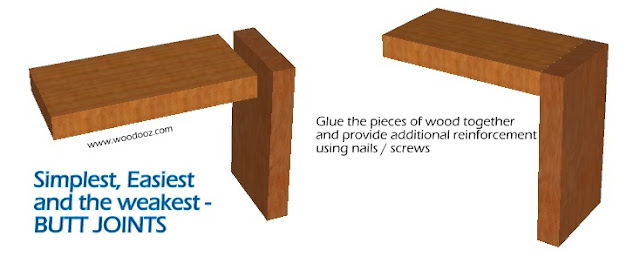

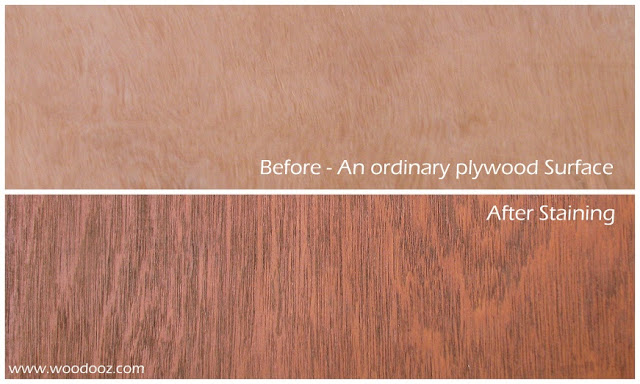

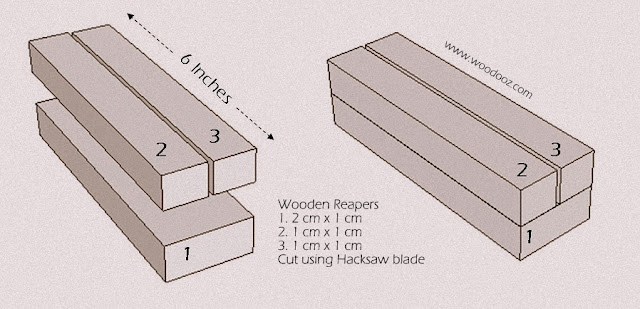

| Deal wood for the legs Plywood for the table top One side teak (OST) for the top finish Rubber bushes | Electric Drill Drill bit for pilot hole Drill bit for counter sink 4 inch screws Glue (Fevicol SR) L Shaped clamps Hammer Headless nails Screw Drivers Emery (Sand) Paper (Grade 80, 100, 120) | Thinner Ramson wood sealant MRF Wood stain Clear Gloss Varnish | Sponge Gada Cloth Vinyl Gloves Table Measurement Height 10.2 inches Length 3 ft Breadth 2 ft |

Linking in : Colours Dekor