| Update : Join our DIY Woodworking group in Facebook. Discuss. Share. Take help. Raise queries. Some interesting discussions are happening at this very moment. JOIN NOW. |

Ever since I started working on basic woodworking as a hobby, I have been on the lookout for workshops / classes that I can attend. It makes it easier to understand concepts from industry experts who are willing to part with their knowledge, than struggling to get answers from non-receptive carpenters or hardware store vendors.

In Chennai, unfortunately, I was not able to find any such workshops. But Bangalore folks seem to be the lucky lot. I reached out to Hamsavardhan to know more about his woodworking workshop. Here’s what he had to say:

Workshop is held at Esthete studio, Tavarekere Road, Near Prestige St. John's Wood Apartments (1km from Forum Mall Koramangala).

2. What is the workshop all about ?

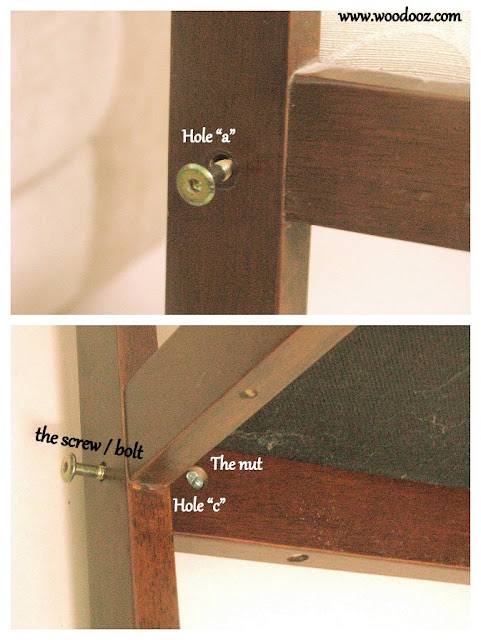

The agenda is to create awareness about wood and working with wood, carpentry, information on various types of wood and wood based products, such as plywood, MDF etc. The workshop will also cover basic tools and joinery techniques. It is an introductory lecture-demo on the science, craft and technology of wood and woodworking, carpentry and furniture making.

3. Who is the workshop for ?

It is a very informative and interactive session for anyone interested in understanding wood products, carpentry and furniture making.

4. How much does the workshop cost ?

This is a free class and is open to all.

5. Do the attendees have to bring anything along with them ?

A notebook to jot down points. Otherwise nothing.

6. When is the workshop normally held ?

The workshop is held on last Sundays of all months. You can “LIKE” the Esthete Facebook page to get information on all upcoming events.

7. Contact information for any further details ?

Feel free to reach out to Hamsa Vardhan at +91 99020 59328.

The next workshop is on the 27th of Jan, 2013 between 1000 hrs and 1300 hrs. I hope Bangaloreans interested in understanding the nuances of woodworking would make good use of the opportunity. I am thinking of planning my next Bangalore trip with the workshop in mind.

Hope you found this post useful. I shall most certainly track other workshops around the country and provide details here for all to benefit from. Do leave a comment and let me know your opinion on this post.

- Somu

About Esthete and Hamsavardhan

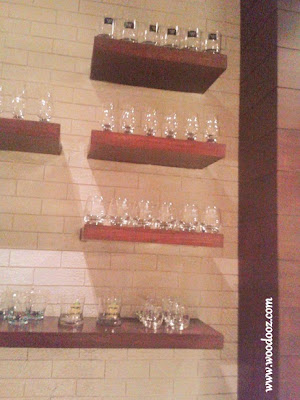

Esthete is a design based company, specializing in Turnkey Interior Design and Execution, Complete Interior Decoration, Designing and Manufacturing of Customized furniture and accessories, Developing new and exciting designs in various materials, especially wood and suggesting space saving ideas for clients.

Hamsavardhan is Esthete’s Founder and Principal Designer. He started his design career as a furniture and interior designer specializing in children’s rooms, along with his partner, Mubina Vazirali, in the early 90’s. Their first clients were C.Krishniah Chetty Jewllers. Later he worked with Architect Omar Nisar as an architectural assistant. Know more about him in his official website.

Disclaimer

This is not a sponsored post. This blog post was written purely for bringing useful information / content to the readers of this blog. Also note that I have not attended this workshop and hence cannot provide any feedback at this point on the workshop itself.

- Somu

About Esthete and Hamsavardhan

Esthete is a design based company, specializing in Turnkey Interior Design and Execution, Complete Interior Decoration, Designing and Manufacturing of Customized furniture and accessories, Developing new and exciting designs in various materials, especially wood and suggesting space saving ideas for clients.

Hamsavardhan is Esthete’s Founder and Principal Designer. He started his design career as a furniture and interior designer specializing in children’s rooms, along with his partner, Mubina Vazirali, in the early 90’s. Their first clients were C.Krishniah Chetty Jewllers. Later he worked with Architect Omar Nisar as an architectural assistant. Know more about him in his official website.

Disclaimer

This is not a sponsored post. This blog post was written purely for bringing useful information / content to the readers of this blog. Also note that I have not attended this workshop and hence cannot provide any feedback at this point on the workshop itself.

+DIY.jpg)

.jpg)