Blog

Easy DIY project

Easy woodworking projects

how to start woodworking hobby

How tos

small DIY projects

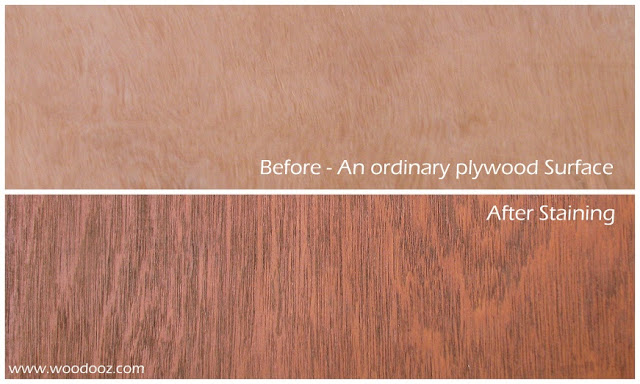

Have you ever been put off by the idea of doing something with wood because of the hard work that it involves? Have you been giving up on executing a thought because you didn't have the necessary tools? Do you like to explore woodworking as a hobby but don’t know where to begin? Here is a list of some simple and easy projects that you can do to give your interest a kick start. Why do I call them simple and easy? All these projects use easily available materials, requires a hack saw blade and don’t take much time to complete.

Further reading: My 17 point recipe on how to start a woodworking hobby

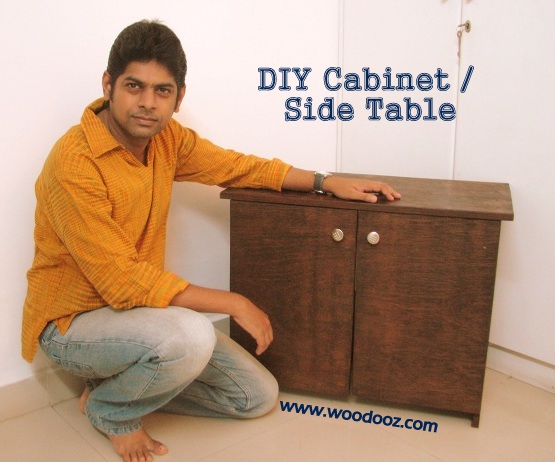

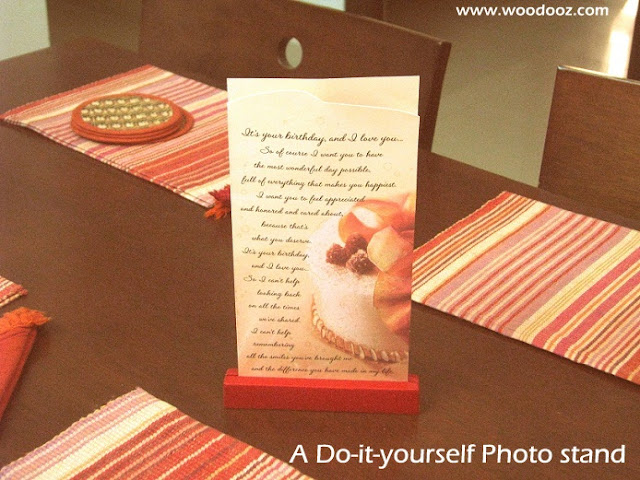

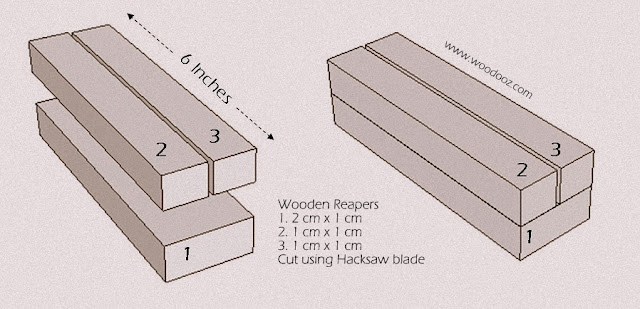

1. DIY Photo Stand (Beginner level)

|

| Simple and easy DIY Woodworking projects |

- If you have a display space at home, this is a really wonderful thing to own. Inspired by a menu card holder, this is one of the easiest projects I have ever done. Takes just a couple of wooden reapers and adhesive and you have your own photo stand.

Further reading: Learn to make a Photo stand yourself

2. A Smart phone holder (Beginner level)

- Another very functional project. I was really glad that I made it. Makes watching Youtube much easier than ever. Again, just a couple of wooden sticks and some glue is all you need.

Further reading: An easy to you-can-yourself-build smart phone holder

3. A Photo frame (Beginner to intermediate level)

- This serves the same function as the photo stand, except that it is a conventional photo frame. This DIY apparently is among the top 5 popular posts in Woodooz. Little bit of creativity and you can have personalized photo frames to hold all your memories together.

Further reading: How to make a photo frame at home

4. Wooden Wall clock (Beginner to intermediate level)

- You can make a simple clock to a really fancy one and all that depend on the thought you put into the projects. However small / big your clock may be, the concept behind making one is just the same. You will need to get the clock mechanism, but beyond that, you can use pretty much any material to make your own clock.

Further reading: Making your own DIY wall clock explained [Video]

5. Broadband router holder (Beginner level)

- This is the ugliest looking holder that you would have ever seen. But, what the heck, it really serves its purpose. The inspiration was a mobile phone charger holder that I saw at a duty free shop in the airport. The design is raw and rough, but it certainly saved us some floor space. Try it out if you think you have a similar need.

Further reading: A broadband modem holder you will love to make

Starting with smaller projects and then gravitating towards bigger and more complex ones can help sustain your newly found interest. And the sustenance is key to your interest growing into a passion that you most certainly love to indulge in. If you let non-availability of materials and tools to discourage you, these 5 projects will help get you back in track. Do you have any other small and easy projects in mind? Leave me your thoughts in the comments section.

- Somu